PRODUCTS

Related Products

Product description:

Permanent magnetic couplings are widely used in various general machinery to connect two shafts to rotate together to transmit torque and motion. Traditional couplings must transmit torque through the mutual connection of the active shaft and the driven shaft. They have complex structures and high manufacturing precision, and are prone to damage to components when overloaded. In particular, when the active shaft and the driven shaft work in two different media that need to be isolated from each other, sealing elements must be used for dynamic sealing. In this way, there is a problem of either increasing the rotation resistance to ensure reliable sealing or leaking due to poor sealing.

Magnetic transmission couplings are non-contact couplings. They are generally composed of two inner and outer magnets, which are separated by an isolation cover in the middle. The inner magnet is connected to the driven part, and the outer magnet is connected to the power part. In addition to the function of buffering and vibration absorption of elastic couplings, the biggest feature of magnetic transmission couplings is that they break the structural form of traditional couplings and adopt a new magnetic coupling principle to achieve force and torque transmission between the active shaft and the driven shaft without direct contact, and can transform dynamic seals into static seals to achieve zero leakage.

It is suitable for occasions with variable load impact, frequent starting and forward and reverse rotation, and also for occasions where the two axis lines cannot be strictly aligned. It is especially suitable for occasions with special requirements for leakage.

Permanent magnetic coupling mainly consists of three parts: inner rotor, isolation sleeve, outer rotor

Inner rotor: generally made of 304 or 316L stainless steel, the liquid contact parts are all made of stainless steel, and the welding light welding seal test is processed. To improve the anti-corrosion performance and increase the product life.

Isolation sleeve: See the accessories area for details

Outer rotor: Magnetic steel electroplating NI treatment, external spray painting, generally made of Q235 material to achieve the purpose of magnetic isolation.

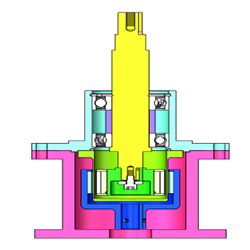

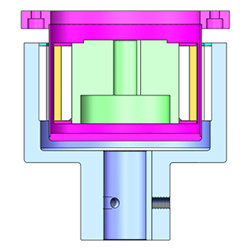

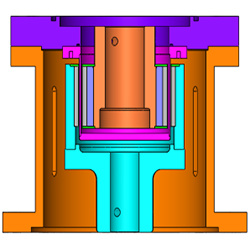

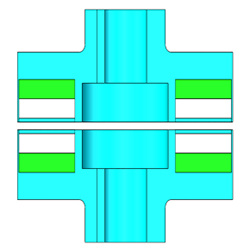

product structure:

|

|

|

|

|

|

Mixing with shaft-01 series |

Ordinary type-02 series |

With support cover-03 series |

Flat type |

Product naming:

KM CS 01- P L00

KM----Ke Ming

CS----Permanent magnet coupling

01----Product structure

P----Represents the material of the isolation sleeve PEEK S represents the material of the isolation sleeve 304/316

L----Medium temperature resistant

H----High temperature resistant

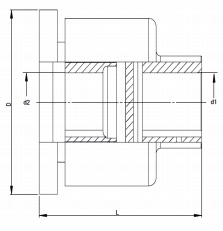

Product Size:

This product is customized according to the parameters provided by the customer. The following dimensions are for reference only.

|

Model |

Torque (Nm) |

d1 (mm) |

d2 (mm) |

L length (mm) |

D diameter (mm) |

|

|

KMCS-10 |

10 |

14 |

12 |

75 |

70 |

|

|

KMCS-16 |

16 |

16 |

13 |

80 |

75 |

|

|

KMCS-25 |

25 |

20 |

17 |

90 |

80 |

|

|

KMCS-40 |

40 |

24 |

20 |

95 |

90 |

|

|

KMCS-50 |

50 |

30 |

22 |

100 |

95 |

|

|

KMCS-100 |

100 |

32 |

24 |

110 |

110 |

|

|

KMCS-150 |

150 |

38 |

25 |

|||

|

KMCS-200 |

200 |

40 |

28 |

140 |

120 |

|

|

KMCS-250 |

250 |

48 |

35 |

|||

|

KMCS-300 |

300 |

55 |

40 |

150 |

125 |

|

|

KMCS-350 |

350 |

60 |

42 |

170 |

||

|

KMCS-400 |

400 |

65 |

48 |

190 |

150 |

|

|

KMCS-450 |

450 |

75 |

50 |

|||

|

KMCS-500 |

500 |

80 |

60 |

210 |

170 |

Product inquiry