PRODUCTS

Permanent Magnetic Coupling

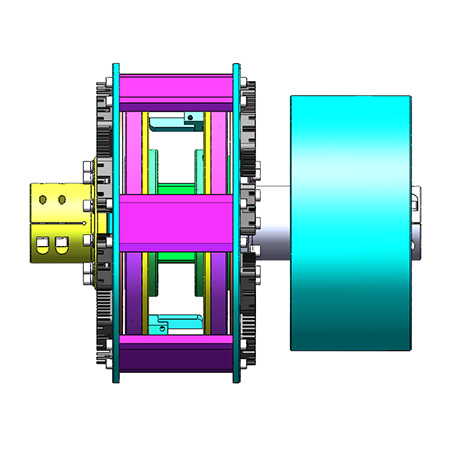

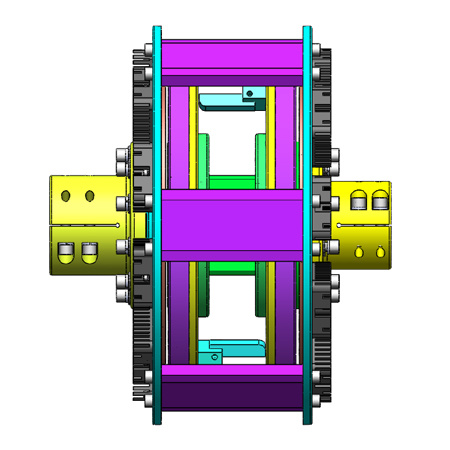

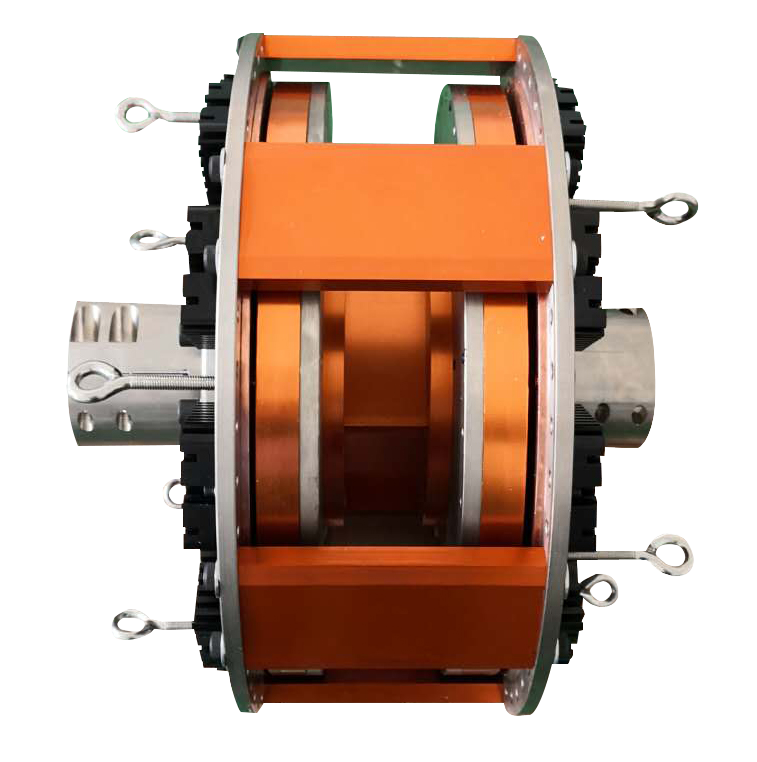

The torque-limiting permanent magnet coupler realizes torque transfer from the motor to the load by means of an air gap between the copper conductor and the permanent magnets. This technology realizes no mechanical connection between the driving motor and the driven load side. The principle of operation is that the conductor rotor is equipped with a copper conductor and a multi-pole permanent magnet on the load side. When there is relative motion (rotation) between the active and passive body, the copper conductor body surface will correspond to each permanent magnet is induced by the eddy current, so as to realize the transfer of torque, when the load suddenly overloaded or jammed, and the load connected to the permanent magnet rotor rotating speed quickly dropped to zero, and connected to the motor copper rotor continues to rotate in accordance with the speed of the motor, and the relative speed difference between the two produced by the The relative speed difference between the two produces the magnetic induction force, which can quickly widen the gap between the two to 38mm (the maximum distance of the gap), thus eliminating the torque transmission between the motor and the load, and can realize the purpose of completely protecting the motor and transmission components.

Product inquiryRelated Products

Product description:

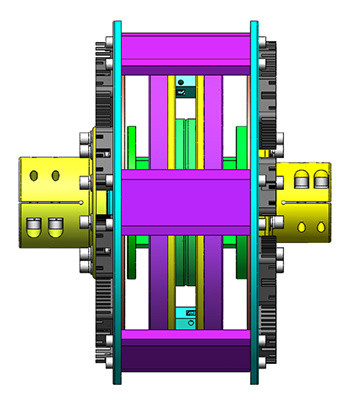

The torque-limited permanent magnet coupler realizes the torque transmission from the motor to the load through the air gap between the copper conductor and the permanent magnet. This technology realizes the non-mechanical connection between the driving motor and the driven load side. Its working principle is: the conductor rotor is equipped with a copper conductor, and the load end is a multi-pole permanent magnet. When there is relative motion (rotation) between the active and passive bodies, eddy currents will be induced on the surface of the copper conductor corresponding to each permanent magnet, thereby realizing the transmission of torque. When the load is suddenly overloaded or stuck, the rotation speed of the permanent magnet rotor connected to the load quickly drops to zero, while the copper rotor connected to the motor continues to rotate at the speed of the motor. The magnetic induction force generated by the relative speed difference between the two can quickly increase the gap between the two to 38mm (the maximum distance of the gap), thereby eliminating the torque transmission between the motor and the load, and can achieve the purpose of fully protecting the motor and transmission components.

Features:

Product description:

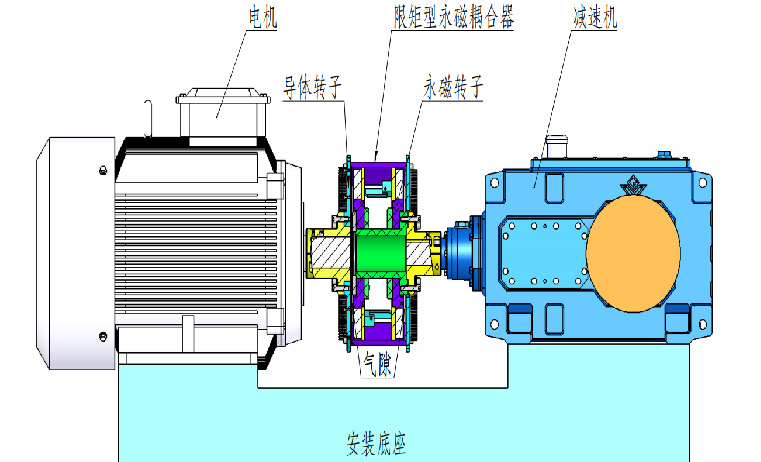

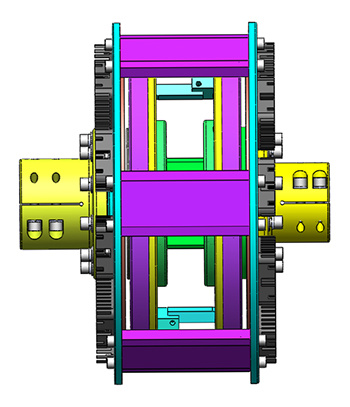

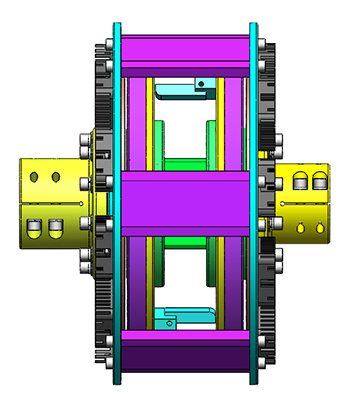

● The motor output shaft is fixed to the conductor rotor, and the load (reducer) input shaft is fixed to the permanent magnet rotor

● The motor starts, driving the conductor rotor to rotate and cut the permanent magnet rotor magnetic field. The conductor rotor generates eddy current, which in turn generates an induced magnetic field, which interacts with the permanent magnet rotor magnetic field and drives the permanent magnet rotor to rotate.

Features:

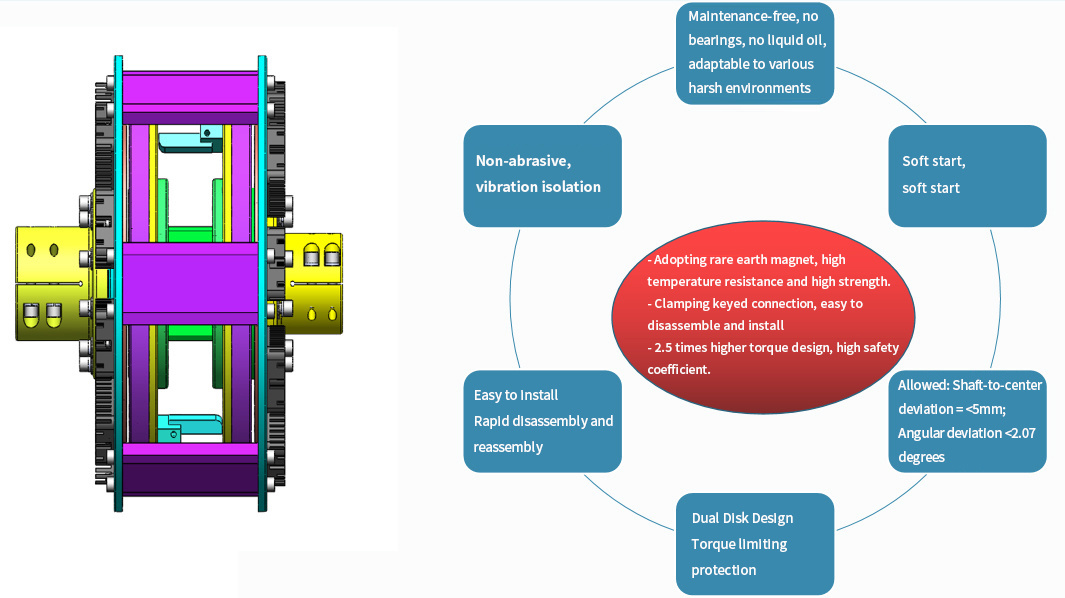

●No physical connection, isolated vibration transmission

●No oiling or power supply, no maintenance required

●Stalling torque limit protection, extending equipment life

●Tolerant centering error, easy to install and disassemble

●Simple and reliable structure, adaptable to harsh environment

Product Categories

|

With brake type |

Normal type |

Illustration of running action

| Increased air gap at startup moment; reduced startup current | After avoiding peak current; air gap returns to normal | Load blocking; instantaneous increase in disk air gap, disengagement |

|

|

|

|

|

|

Features of Comin Permanent Magnetic Coupler

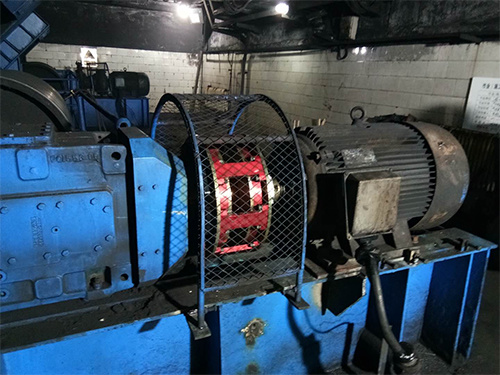

Case Introduction-Conveyor Belt Replacement Liquid Coupling Retrofit

Conveyor belt renovation of the first steel plant

The original hydraulic coupler has just been used for one year, and oil leakage is often found; the vibration is out of the normal range, and has been calibrated and aligned many times, which has seriously affected the normal production.

Solve the problem:

It was replaced with a magnetic coupler of the same power and quickly installed and debugged. It has been running without any faults so far.

Actual effect:

Trouble-free greatly reduces maintenance costs and ensures continuous production. It can automatically disengage in case of overload and quickly recover after the problem is solved.

案例介绍-输送带更换软启动改造

Conveyor belt renovation at petrochemical terminal

The mucus soft starter is leaking oil badly.

Solve the problem:

Replace it with a magnetic coupler of the same power to achieve the soft start function.

Expected results:

Trouble-free greatly reduces maintenance costs and ensures continuous production. It can automatically disengage in case of overload and quickly recover after the problem is solved.

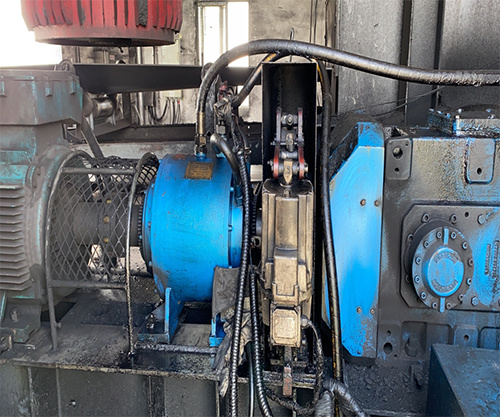

Case Introduction-Coal Mill Liquid Couple Transformation

A thermal power company

The original liquid occasionally leaks oil and the vibration is abnormal. The horizontal vibration is 0.55mm and the vertical vibration is 0.48mm.

Solve the problem:

Replace it with a magnetic coupler of the same power, quickly install and debug, and run it without worries.

Actual effect:

Horizontal vibration 0.16mm, vertical vibration 0.12mm. Noise reduction and vibration reduction ensure the safe and long-term operation of the entire transmission chain

Case Introduction-Heat transfer fan

Cold rolling and galvanizing workshop of the second steel plant

Heat transfer fan, usually the motor is directly connected to the fan impeller, and the operating temperature is 70-80 degrees.

Solve the problem:

Isolate heat transfer and extend equipment life.

Actual effect:

Reduce vibration, isolate heat conduction, and extend equipment life.

Case Introduction-Conveyor belt dual drive transformation

Cement conveyor belt dual drive transformation

In a dual-drive system, the motor speeds on both sides cannot be completely synchronized, the belt service life is short, and the currents on both sides are inconsistent and differ greatly.

Solve the problem:

Actual effect:

After the transformation, the current difference between the two sides is less than 1A.

Product inquiry