PRODUCTS

Permanent Magnetic Couplings

Permanent magnetic coupling is a kind of high-performance equipment utilizing the principle of magnetic force to realize power transmission, which is widely used in various industrial fields. The following is a detailed introduction of the permanent magnetic coupling products:

Product inquiryRelated Products

Product Overview

Permanent magnetic coupling is a contactless force transmission device, which transmits power from one rotating part to another rotating part through the attraction of magnets without any physical connection between the two parts.

There are 2 main types of magnetic drive couplings: flat permanent magnetic couplings and coaxial magnetic couplings.

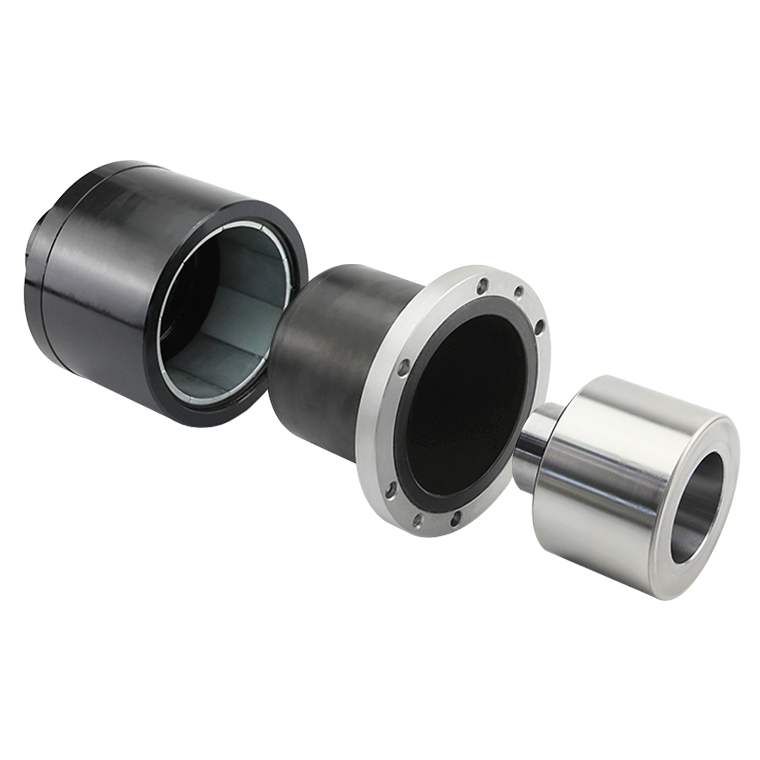

Working Principle: Coaxial permanent magnetic coupling consists of outer magnet, inner magnet and isolation sleeve. The inner and outer magnets are composed of permanent magnets magnetized along the radial direction and magnetized in the opposite direction, the permanent magnets are arranged alternately along the circumference with different polarities and fixed on the mild steel steel ring to form a magnetic circuit breaker.

The isolation sleeve is made of non-ferritic high-resistance materials, generally austenitic stainless steel. At rest, the outer magnet of the N pole (S pole) and the inner magnet of the S pole (N pole) attract each other and into a straight line, at this time the torque is zero. When the outer magnet is rotating under the drive of the power machine, at first the inner magnet is still at rest due to friction and resistance of the driven parts, at this time the outer magnet starts to offset a certain angle relative to the inner magnet, due to the existence of this angle, the outer magnet's N-pole (S-pole) on the inner magnet's S-pole (N-pole) has a pulling effect, and at the same time, the outer magnet's N-pole (S-pole) has a pushing effect on the inner magnet's previous N-pole (S-pole), which has a pushing effect on the inner magnet's N-pole (S-pole). At the same time, the N-pole (S-pole) of the outer magnet has a pulling effect on the previous N-pole (S-pole) of the inner magnet, so that the inner magnet has a tendency to rotate with it, which is the working principle of the push-pull magnetic circuit of the magnetic coupling. When the outer magnet of the N pole (S pole) just located in the inner magnet of the two poles (S pole and N pole) between the resulting push and pull to reach the maximum, thus driving the inner magnet rotation. In the transmission process, the isolation cover separates the outer and inner magnets, and the magnetic lines of force pass through the isolation cover to transmit the power and motion of the outer magnet to the inner magnet, thus realizing a contactless sealed transmission.

Features

● High-efficiency power transmission: the permanent magnetic coupling adopts advanced magnetic coupling technology, which can ensure the efficient power transmission and reduce energy loss at the same time.

● No need for physical connection: the two rotating parts are connected magnetically without the use of traditional mechanical couplings, thus avoiding mechanical wear and corrosion problems.

● Long service life and low maintenance: Due to the lack of physical contact, permanent magnetic couplings experience minimal wear and tear, resulting in a longer service life and lower maintenance costs.

● Strong anti-interference capability: permanent magnetic couplings are highly resistant to electromagnetic interference and radiation, making them suitable for use in demanding industrial environments.

● High adaptability: able to work stably under various extreme environments, such as high temperature, high pressure, strong corrosion and high vacuum.

Application Areas

Permanent magnetic couplings are widely used in the following fields:

● Chemical industry: for the transmission of pumps, fans and other equipment, especially in corrosive or flammable and explosive environments.

● Food and pharmaceutical industry: to ensure the hygiene and safety of products and avoid cross contamination.

● Aerospace: used in the transmission system of precision equipment such as satellites and spacecraft.

● Semiconductor and electronics industry: used in environments with high vacuum and high cleanliness requirements.

● Medical equipment: used in various precision medical instruments, such as MRI, CT, etc.

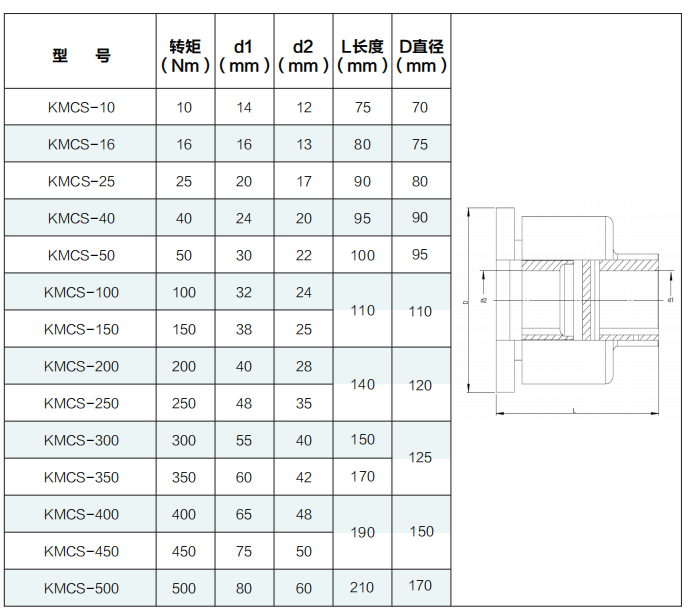

Technical Parameters

● Torque range: depending on the model, it can provide torque transmission capacity from a few Nm to several thousand Nm.

● Speed range: capable of adapting to a variety of applications from low to high speeds.

● Operating temperature: -40°C to +350°C depending on material and design.

● Protection ratings: IP65 to IP69K, depending on the application.

Customization Services

We offer a full range of customization services, including but not limited to:

● Special dimensions and torque: design and manufacture PM couplings to meet specific requirements based on customer's specific needs.

● Material selection: Provide a variety of material options to meet the requirements of corrosion and wear resistance in different environments.

● Performance testing: conduct comprehensive performance tests before leaving the factory to ensure that the performance of the products meets the requirements of customers.

After-sales service

We promise to provide customers with high quality after-sales service, including:

● Installation guidance: Provide professional installation guidance and technical support to ensure that customers can use the permanent magnetic couplings correctly and effectively.

● Quality Assurance: All products undergo strict quality control and testing, providing a limited period of quality assurance.

● Technical Support: A specialized customer service team is set up to answer customers' questions and provide technical support at any time.

For more product information or to get a quote, please contact us; we are looking forward to cooperating with you to promote the development of industrial automation.

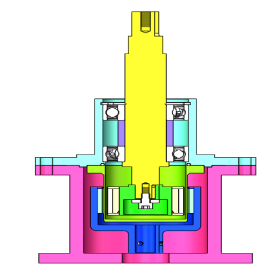

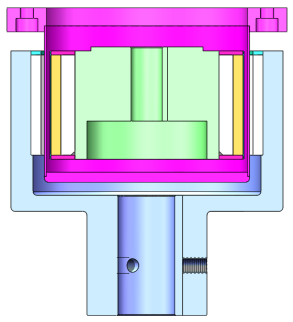

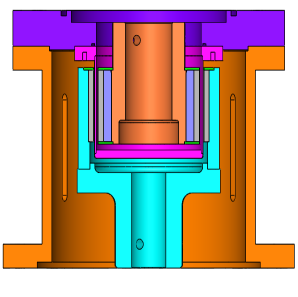

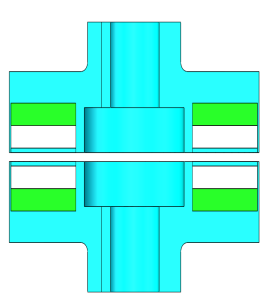

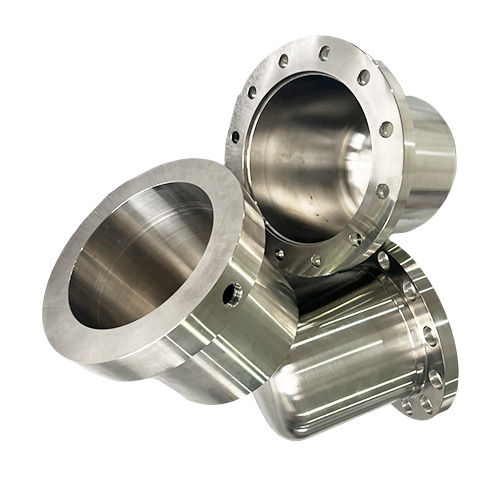

Product structure

|

|

|

|

|

|

Stirring with Outlet Shaft-01 Series |

General type-02 series |

With Support Cover-03 Series |

Planar |

Product Code: KMCS01-100PL00, KMCS02-50SH00

|

KM |

Ke Ming |

CS |

Permanent magnetic coupling |

|

01 |

Product structure |

100 |

Torque |

|

P |

Representative isolation sleeve PEEK material |

S |

Representative isolation sleeve 304/316 material |

|

L |

Resistant to medium and low temperatures |

H |

High temperature resistance |

Product Size:

This product is customized according to the parameters provided by the customer. The following dimensions are for reference only.

|

|

|

|

Product inquiry