PRODUCTS

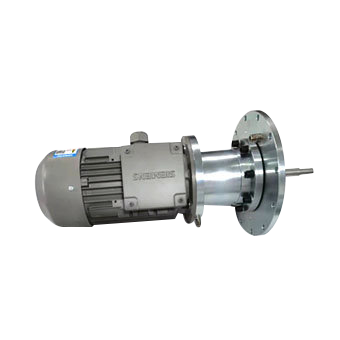

Permanent Magnetic Stirrers

Permanent magnet stirring is a permanent magnet coupling instead of the original common coupling, using magnetic force to produce a completely sealed space inside the stirrer, thus realizing no leakage of liquid or gas.

Product inquiryRelated Products

Product Overview

Permanent magnet stirrer is widely used in various industrial fields, such as chemical, pharmaceutical, food processing, metal casting and so on. It generates a stable magnetic field through the built-in permanent magnet, which drives the stirring impeller to rotate in the liquid (gas), realizing the purpose of homogeneous mixing, dissolution, suspension and so on. Compared with the traditional mechanical stirrer, the permanent magnet stirrer has the advantages of no shaft seal, no leakage, simple maintenance, etc. It is especially suitable for dealing with flammable, explosive, toxic or corrosive media.

Product Features

● High-efficiency stirring: permanent magnetic stirrer can provide uniform and stable stirring effect, improve product quality and production efficiency.

● Safety and environmental protection: Since there is no mechanical seal, the permanent magnetic stirrer can effectively avoid leakage and protect the environment and the safety of operators.

● Easy maintenance: simple structure, no need for complex mechanical transmission parts, reducing maintenance costs and time.

● Strong corrosion resistance: it is suitable for stirring various corrosive media, which improves the service life of the equipment.

● Energy saving and high efficiency: permanent magnetic stirrer usually adopts high efficiency motor drive, low energy consumption, in line with the requirements of energy saving.

Application Fields

Chemical industry: used for mixing, reaction, suspension and other processes of chemicals.

● Pharmaceutical industry: used in the synthesis, extraction and preparation of pharmaceutical products.

● Food processing: used for mixing, homogenizing and tempering of food materials.

● Metal casting: used for alloy stirring in the melting process to improve the quality of castings.

● Laboratory: for small-scale experiments and research, such as cell culture, chemical analysis, etc.

Technical Parameters

● Stirring capacity: according to different models, the stirring capacity ranges from a few milliliters to several thousand liters.

● Stirring speed: Various speed ranges are available to meet different stirring needs.

● Power Requirement: usually need to be connected to AC power supply, some equipment may have battery drive function.

● Temperature range: Depending on the material and design, it can be adapted to different temperature working environments.

Customized Service

● Special sizes and shapes: design and manufacture permanent magnet stirrers to meet specific application requirements according to customer specific needs.

● Performance optimization: provide performance optimized permanent magnetic stirrers for specific application environment and requirements.

● Rapid Prototyping: Respond quickly to customer's sample requirements to speed up the product development and testing process.

After-sales service

● Installation guidance: Provide detailed product installation and use guidance to ensure that customers can correctly and effectively use the permanent magnetic stirrer. ● Quality Assurance: All products are guaranteed to be of high quality.

● Quality Assurance: All products undergo strict quality control and testing, providing a limited period of quality assurance.

● Technical Support: A specialized customer service team is set up to answer customers' questions and provide technical support at any time.

For more product information or to get a quote, please contact us; we look forward to working with you to improve productivity and product quality.

Product inquiry